-

-

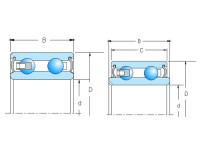

Product name: in stock BD305220 4606-4AC2RS bearing

-

-

Price: ASK

-

-

Post date: 2022-03-10

-

-

Stock Quantity: 1000

-

4606-1AC2RS bearings are becoming more and more unitized, with the number of parts decreasing from the first-generation to the third (GEN3), and evolving into lightweight, compact products.

UNIMOTION Bearing is strictly implementing ISO 9001, 14001, and relevant industry quality standard system and environment protection. We distinguish ourselves by: Abundant experience; Special facilities and instruments as well as the inspection methods; Strict procedure of purchasing the raw material.

Introduction

Working together with over 20 Chinese leading factories, UNIM relies on China completiveindustry resources and providesyou with the optimum solution. UNIMhas over ten-year experience in making conventional bearings, precise bearings and non-standard bearings. UNIM also produces and exports bearing parts (roller, ball, seal, ring and so on), chain, sprocket, pulley and such other machinery parts.

Following strict quality control system, all the members of UNIM are strictly implementing ISO 9001, 14001, and relevant industry quality standard system and environment protection. We distinguish ourselves by: Abundant experience; Special facilities and instruments as well as the inspection methods; Strict procedure of purchasing the raw material.

The team of research, development and production management with high quality staff;

In order to make the better support for our customers to produce and develop their products and to expand their market, we try best to improve ourselves on the company management, product design and staff training.

Business Concept

Company Organization

UNIM Incorporation CHANGZHOU UNIM CO., LTD Global sales, Service, Sourcing, Quality control Local offices at the important production factories and bases

-Communicating organizing Affiliated factories cooperative partners North East China Production Base.

-Producing big size bearing Luoyang Production Base -Producing precise bearing Changzhou Production Base.

-Producing needle roller bearing and roller bearing Hangzhou Xiaoshan Production Base -Producing automotive bearing

High Quality Raw Material

By always selecting the best local raw materials, carrying out the quality control systems strictly, applying advanced precision processing equipment and measurement instruments, as well as advanced product designs and first-class manufacturing process, UNIM is approved to be able to provide all customers with expertise ,application services and total solutions.

Carefully choose raw material suppliers in accord with Supplier Approval Procedure, purchase the domestic top raw material according to incoming Inspection Procedure, so UNIM ensure consistency of bearings. All raw materials conform to national industry standards. Bearing materials are mainly high purity moulded steel, which can improve service life of bearings, ensure high reliability and reduce unexpected downtime for users. In order to ensure quality of raw materials and outsourced parts used in the manufacturing of high-quality bearing products, we have formulated strict incoming Inspection Procedure, which contains inspections of chemical compositions, high-amplified and low-amplified metallographic structure of raw materials, physic-chemical analysis of outsourced parts.

Strict Quality Assurance System

We are strict in quality management and control of our products.In our multi- varieties and continuous mass production, the strict quality system is vital for stable quality of products. ISO 9001 quality management system of UNIM was certificated by DNV in 1997, and TWB is one of few domestic bearing enterprises certificated by a foreign authoritative organization.

Quality Control Process

By quality planning in advance, we have quality management system as a guarantee concerning the processes from products design, raw material purchasing, storage and production to finished goods inspection, package and shipment, etc.

Besides, we have our own physical & chemical laboratory, which makes it possible to inspect each batch of raw materials for the purpose of assuring the high quality.

Setting up a measuring & testing room, TWB has already been equipped with a high-precision measuring and testing equipment to make sure the process measuring precision.

Product Quality Tracing System

According to the system requirements, we establish the strictest product quality tracing system and parts sync-document tracking system to trace all production procedures of each order.We complied with quality operation instruction strictly, conduct initial inspection and regular inspection, file relevant records and guarantee key process parameters are under control.

All process control records are consolidated and filed at least for 2 years. Religious control procedures are fully fulfilled in whole production to ensure the products always meet the customer's demands.

Continuous Improvement System

The company sets a target of zero defects. In order to achieve this goal, we should continuously enhance our process improvement and quality management practices. By the way, company should perfect quality information and communication channels to help related employees and departments to be involved in the whole work of quality management.